When it comes to plastic manufacturing at Westec, injection molding is only a part of the process. We are passionate about offering full-service manufacturing at Westec. By offering a full range of secondary operation services, we can add value to our molded parts and assemblies. We’ve provided ancillary services for our customers for many years and we continuously strive to grow our capabilities as technology evolves.

Customized Solutions for Injection Molded Parts

We understand projects often involve unique solutions requiring our team to offer customers many types of secondary operations. Some of the available services we provide include:

- Pad Printing

- Roll Printing

- Vibration Welding

- Ultrasonic Welding

- Laser Engraving

- Hot Stamping

- Heat Staking

- CNC Machining Operations

- Packaging

- Contract Assembly

In addition to these services, certain projects might involve a more tailored approach with fixturing, labeling, and functional testing specific to the customer’s design. Westec offers many customization options; our customers know they are getting precision parts engineered for their specific purposes.

Our Customers’ Top Choice for Value-Added Services

With Westec being an entirely in-house injection molding company, we can vertically integrate processes and be the “one-stop-shop” solution our customers need. Having our operations in one facility consolidates accountability if issues arise. It streamlines the entire process so that completed products are made quickly and efficiently.

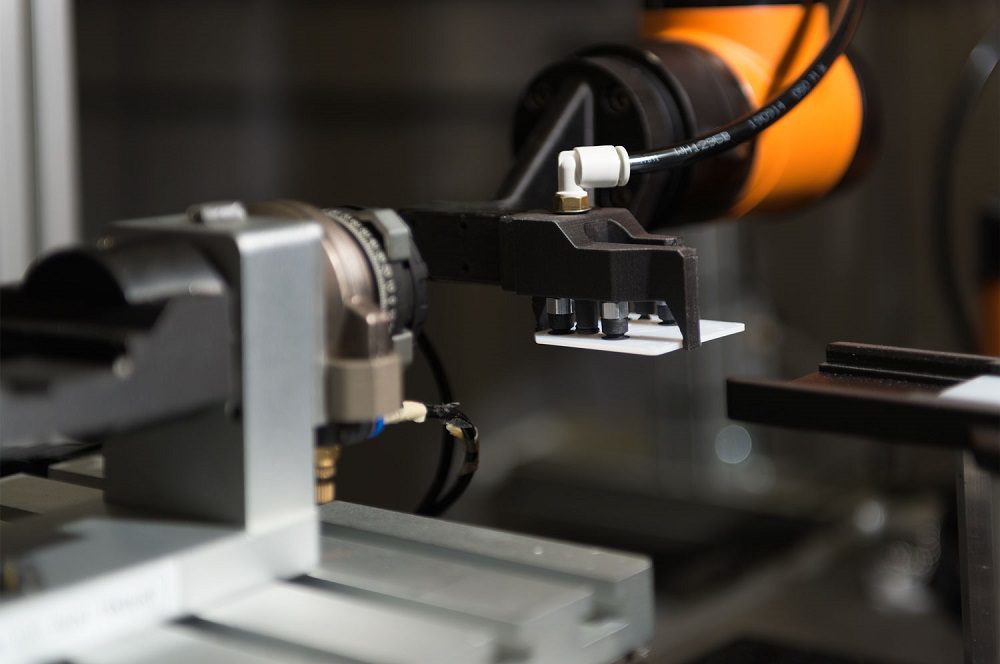

No matter what our customers require with their specific components, Westec can deliver expert value-added services. As an example, Westec has a customer who had a molded part that required an ultrasonically welded sub-assembly be ultrasonically welded to a base part. The customer struggled with successfully joining the two components. Westec’s team investigated the issues and determined vibration welding the second weld instead of ultrasonic would guarantee a stronger bond. To ensure the assembly was functional and the part’s multiple chambers were fully welded, each assembly was then pressure-tested and leak-tested on a custom inspection unit that examined each chamber individually. The result of Westec’s efforts was an expertly crafted component our customers could trust was made to the highest possible standards.

Quality and Dedication Start with Us

Westec Plastics is a progressive injection molder with an emphasis on the medical and biotech industries. When you align with us, you work with a multi-faceted partner that operates with a sense of urgency and accountability within every department. Our value-added operations and offshore tooling, in addition to our full-service, in-house tooling room, and state-of-the-art injection molding equipment, make us a “one-stop-shop” partner. At Westec, we work with an unwavering commitment to quality.

Want to learn more about Westec’s value-added services? Contact us today to start a conversation.