Your Single Source Contract Manufacturing Partner

Westec Plastics Corporation offers our customers many types of secondary operations which allows us to be a single source and value-added contract manufacturing partner to our customers.

Westec Secondary Operations – Services & Support Features

Available services, including but not limited to:

- ISO Class 6 Secondary Operations Clean Room

- ISO Class 7 Secondary Operations Clean Room

- ISO Class 8 Clean Room Assembly

- 1-6 Colors for Pad Printing

- Roll Printing

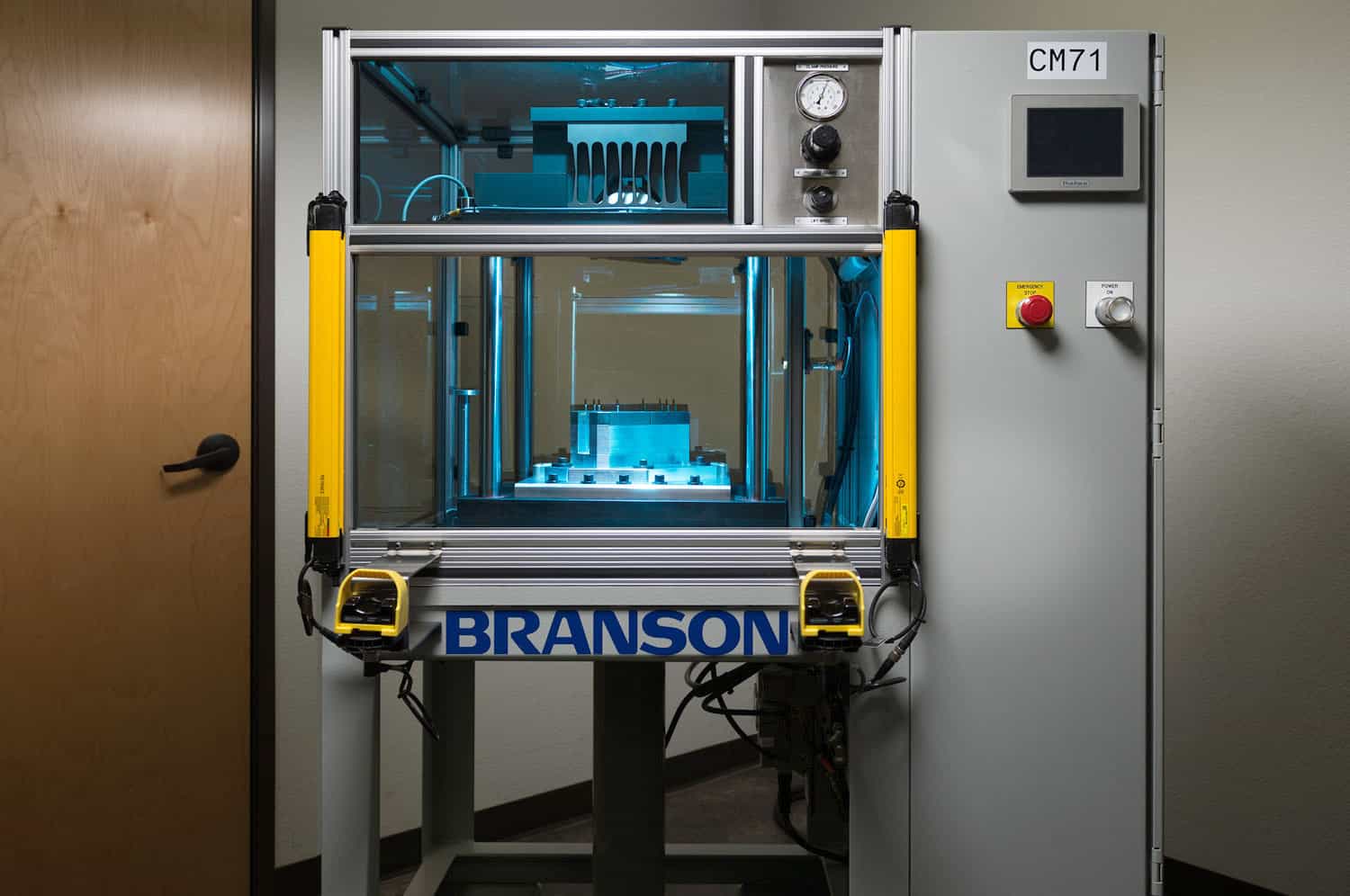

- Vibration Welding

- Ultrasonic Welding

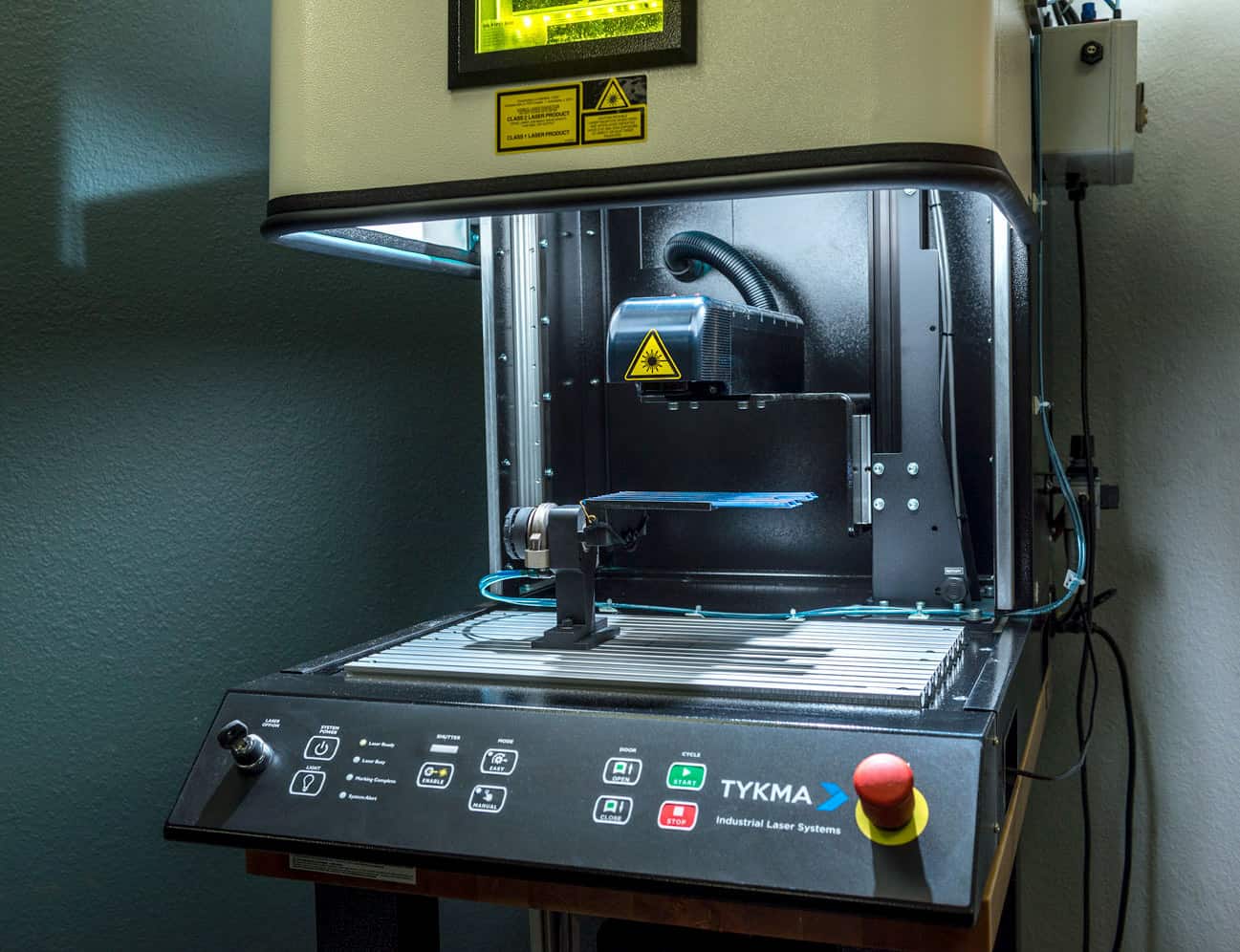

- Laser Engraving

- Hot Stamping

- Heat Staking

- Secondary CNC Machining Operations

- Packaging

- Contract Assembly

- UL Approved Supplier

- Others as required

Westec Plastics — your SINGLE SOURCE partner for all of your contract molding and secondary operation requirements.

Laser Engraving Machine Used In Secondary Operations For Plastic Injection Molded Parts

Collaborative Robots (Cobots) Work Alongside Westec Employees

Roll Printing - Pad Printing with Tight Tolerances for Plastic Injection Molding and Secondary Operations

High Intensity Vibration Welding for Plastic Injection Molded Parts and Secondary Operations